Industries & Case Studies

As the global economy becomes increasingly industrialised, protecting supply-chains from corrosion and weather damage is paramount to success in all industries.

It is estimated that the direct cost of corrosion amounts to 3% of all produced goods and services.

But this doesn’t need to be the case with your business. Intercept Technology’s products can be applied in almost every industry, including:

Electronics & Telecommunication

Protection of sensitive electronic equipment faces corrosion and electrostatic discharge (ESD). Component failures are usually a combination of corrosion and ESD. By utilizing Intercept Technology products for protection against both can be achieved.

- 100% Corrosion Protection

- Full effective ESD-Protection at all humidity levels

- Contamination free

- Reduction of cost by using reusable and recyclable materials

- Optimization of processes

Subject Case:

Major Telecommunications Company

Situation:

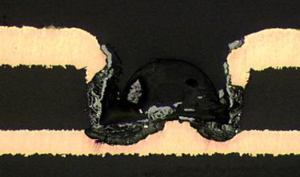

India/Asia: Protection of PWB (Printed Wiring Boards) and PCB (Printed Circuit Boards). Providing corrosion and solderability protection in severe environments. Copper based PWBs and PCBs have major corrosion issues within weeks of manufacture, even though the boards were in sealed ESD shielding bags.

Intercept Solution:

Static Intercept 3mil Bags

Client switched from non-recyclable ESD Shielding bags to 75 micron (3 mil) Static Intercept.

Result:

- Solution suitable for short to long term protection (up to 15 plus years) for corrosion and ESD protection.

- PWBs protected for short term applications as well as long term shipment and storage without fear of the Copper portions of the board or via connections being attacked by the high levels of sulphur-based pollutants in the air and environment. The sulphur-based gases were severely damaging the Copper rendering the boards not usable and preventing solderability and functionality.

- Replacement of non-recyclable ESD Shielding Bags with full recyclable Static Intercept bags.

- Protection of PWBs as both individual boards and stacks.

Subject Case:

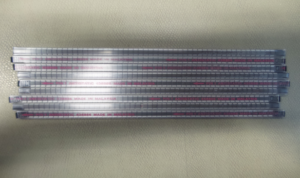

International Aerospace Company – Protection of PCBs

Situation:

Discontinued semiconductor PCB stacking and storage for an aerospace customer. Task was to keep inventory without corrosion for more than five years. Previous problems included insufficient space for inventory and quality issues.

Intercept Solution:

RIBS MVTR Ultra – Repacking parts into Intercept Technology specialized material called RIBS MVTR Ultra (Reactive Intercept Barrier System – Moisture Vapor Transfer Rate – Ultra).

Result:

- Cost savings compared to earlier solutions

- Freed inventory space at customer site

- Full corrosion protection

Automotive

In the automotive industry despite Just-In-Time (JIT) deliveries preservation remains an important task. Automotive parts are still shipped around the world and stored long-term (obsolete parts, spare parts). The new shift to EVs (electric vehicles) will not make preservation obsolete. It will merely change preservation focus to electric components.

- Simplification of processes

- Process cost reduction

- Utilization of oil-free clean parts

- Avoidance of cleaning oil-treated parts (for preservation purposes)

- Higher loading densities for total solutions

- Environmental effects, including reduced waste-water (washing) and reduced plastic waste

- Avoidance of repacking parts during long-term storage

- Simplification of stacking & packing

Subject Case:

International Market Leader in Automotive

Situation:

This major corporation faced the situation to store crankshafts for a period of effectively for three years. A solution was needed to efficiently reach that goal.

Intercept Solution:

Static Intercept 4mil plastic film bags plus 4U desiccant bag.

Result:

By using Intercept anti-corrosion plastic film three years of protection were achieved without the usage of oils or any other surface chemicals. Not only stayed the parts corrosion free. At the same time a process cost reduction of over 40% was realized. Additionally, the chosen method was extremely beneficial for the environment by avoiding unnecessary washing of the parts at the end of the storage period.

Subject Case:

International Automotive Company Faces Corrosion Of Water Pumps For Its 3-Cylinder Engines

Situation:

For long-term storage of water pumps for 3-cylinder engines for up to 15 years a solution was needed to prevent corrosion effectively.

Intercept Solution:

Static Intercept flat bag with desiccant

Result:

- Significant process cost reductions

- No repacking of parts needed

- No oils used for preservation

- No outgassing packaging material used

- Corrosion and full ESD protection

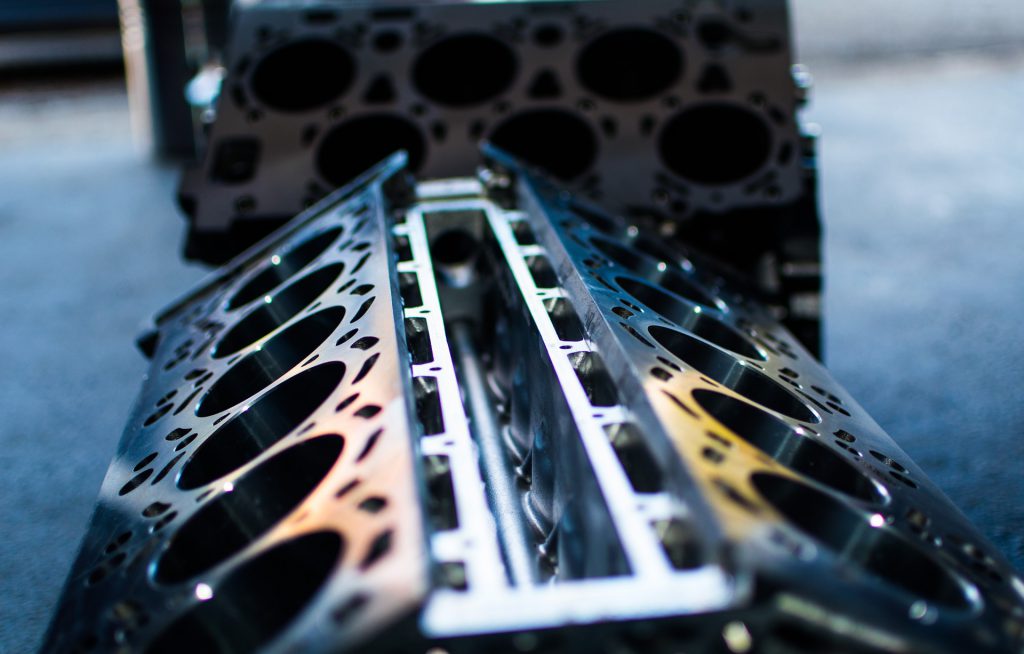

Subject Case:

International Market Leader in Automotive

Situation:

Major car brand faces the problem of efficiently store car motor blocks. The engine blocks need to be packed directly after washing and drying. A storage time of at least six months is required before the parts are used in consecutive processes including further storage and transportation.

Intercept Solution:

Blocks packed in 4mil Static Intercept film, desiccants added

Result:

- Reducing process cost significantly

- Engine blocks are preserved without oil & wax

- Immediate use after the plastic film is removed

- No need for additional washing (to remove oil & wax that were added for preservation purposes)

Oil & Gas

Mining

Machinery

Energy

Rail

Maritime

Industries like oil & gas, mining, energy, maritime and rail have similar requirements. Equipment and components are of high value and at the same time of huge nature. Transport is usually by sea. Specific long-term storage is often needed.

The specific requirements for transport and storage of valuable equipment and large components face severe environmental conditions. Harsh climates with high humidity levels, cold and hot temperatures during winter and summer require superior protection against corrosion and elements. Jungle, desert, coast, sea areas with insecure roads also cause danger by stones and small birds.

- Protection against weather elements (wind, dust, moisture)

- Corrosion protection in high humidity environments close to the sea and on sea

- Shielding against harmful UV-light

- Outdoor long-term protection of max. 10 to 15 years

- Protection without the use of oil, wax or grease

Subject Case:

Oil & Gas Company in Australia

Situation:

Task is to protect is to store equipment for offshore oil and gas fields in Australia. The equipment comprises of a compressor unit, desiccant tanks-control box, cooling unit, spare parts. Previously the storage of equipment brought severe corrosion problems.

Intercept Solution:

Application Intercept Shrink Film and Static Intercept bags

Result:

- Corrosion could be prevented during the storage time

- Equipment were at all times ready to use without harming its function

- Significant savings achieved for the preservation and storage system

Subject Case:

Mining Venture in Australia – Protection Of Wheel Ends Haul Truck And Other Parts

Situation:

Task is to preserve mining equipment during road shipment to the mine site and consecutive storage. Previous problems included corrosion, contamination during transport and storage. Requirements: No application of oil at sender and de-oiling at receiver’s end.

Intercept Solution:

Pre-made bags (kits) 8mil Static Intercept shrink-film then second layer 8mil Power-shrink film high UV protection with desiccant.

Result:

- Cost effective solution for the whole transportation and storage process

- Elimination of corrosion

- Protection from aggressive acids and foreign metal contamination during transportation and storage

- Zipper access for rotation of shaft and bearings

- UV protection

- No application of oil at sender and De-oiling at receiver’s end

- No OH&S and Recycling issues

Subject Case:

Machine Manufacturer Faces Sea Freight Transportation and Corrosion

Situation:

Export of water treatment equipment from China to Japan and Israel. Previously rust stains and corrosion appeared on the equipment’s body surface during sea shipment.

Intercept Solution:

Using Intercept Shrink Wrapping to protect the equipment during sea shipment.

Result:

- Preserved current pristine condition of the equipment

- Prevented corrosion during transport via sea

- Protection against aggressive sea environment

- Provide protection during storage time upon arrival in Japan and Israel prior to set up

Subject Case:

Spare Turbine Long-Term Storage for Energy Generation (Power Plant)

Situation:

Long term critical spare storage of the largest turbine in the Southern Hemisphere. Due to the unique requirements for long term storage of such a large turbine, while the individual blades were small, previous methods were not able to accommodate preservation requirements.

Intercept Solution:

Intercept Shrink Film, 8mil, desiccants.

Result:

- Cost effective preservation and protection from corrosion for 10 years

- Creation of a reactive barrier to corrosive gases

- Avoiding oiling for protection and de-oiling prior to usage

- Achieving high flexibility to put a critical spare into use immediately

- Wrapping allowed for the critical ability to rotate the turbine on its pre-scheduled rotation schedule during storage

Subject Case:

Manufacturer of Rail Stock – Transport of Rail Wagons From China For Mining Industry in Australia

Situation:

Task was to ship rail wagons China to Australia via sea freight in an open deck situation. Often this brings strong winds and exposure to water/moisture. Therefore, high possibility of corrosion during transport is be expected. Problems with several protection methods/packaging ways prior, including difficulties of dealing with oiling and waxing which produced high cost and were not effective.

Intercept Solution:

Double layer of protection, inside Intercept Shrink Film 8mil, outside Power Shrink Film, desiccants.

Result:

- Cost savings by not applying oil or wax were achieved

- No cost for removing any oil or wax at destination (Australia)

- No corrosion found upon arrival

- Shrink Film is 100% recyclable, no cost for disposing used packaging materials

Subject Case:

Protection Of Naval Equipment For Maritime Company

Situation:

Navy pumps had to be protected against corrosion for road transport and storage. Previous problems included corrosion and intrusion of moisture.

Intercept Solution:

Intercept Shrink Film, with desiccant, second layer of Power Shrink Film with UV protection, application of ‘do not cut’ stickers and warning tape.

Result:

- Cost effective solution compared to previous solutions

- Elimination of corrosion during transport and storage

- Protection from corrosive gases, moisture, dust and UV during transportation and storage

- Zipper windows for lifting

- No OH&S issues

- No application of wax or oil at sender and de-oiling or removal of wax at the receiver

Aerospace & Defense

Aerospace and defense have very high requirements for preservation. This is due to the nature of the components which are used within the most valuable and technical advanced systems. This goes along with the highest standard otherwise only found in the nuclear industry. Components are most sensitive in regard to corrosion, moisture and impact by other elements.

- Superior Protection of costly components

- Permanent protection against electrostatic discharge and corrosion

- Protection without oils and grease

- Compatibility with weapon grade materials

Subject Case:

Portable Hangar for Military Aircraft

Situation:

Requirement is to provide physical and corrosion protection for deployed aircraft. Protection method should be portable and easy to set up. A continuous protection against corrosion and degradation was requested. Previous included airplane components were not functioning properly due to corrosion and physical damage.

Intercept Solution:

Application of a re-usable and portable (and a different model is free standing) hangar liner that can move with the airplane to various locations to provide physical protection from the elements, weather and sand, as well as corrosion protection for sensitive components. Hangar liner made of reinforced Static Intercept Film to enable multiple re-uses. De-humidification system to purify interior.

Result:

- The hangar provides a portable method to provide physical and corrosion/degradation protection to airplanes during deployment.

- Fast set-up, fast disassembly

- Protection against aggressive (sea-) environments, including corrosive gases, weather elements

- Combat readiness, instead of tens of minutes to remove preservation wrap, ready within seconds

Subject Case:

Aerospace Component Manufacturer Project For Long-Term Storage

Situation:

Protection for long term storage of airplane wings / components stamping tools. In particular, stamping tools protection for up to three years storage. Requirement for storage was a total solution for whole time period of storage.

Intercept Solution:

Tools were wrapped in 8 mil Intercept Shrink Film with appropriate desiccants being added.

Result:

- Cost effective solution throughout the whole three-year storage period

- The use of Intercept Film allowed for long term storage without the need to rewrap the tools on a bi-annual basis

- The addition of a zipper access door would allow for easy reviewing during storage (with re-application of fresh desiccants with every opening and inspection process).

Subject Case:

Sikorsky 73 A Helicopter Road & Sea Shipment from Australia to Mexico

Project:

Task was to transport helicopters from Australia to Mexico. The route included road transport and sea shipment. Previously corrosion and contamination during sea transport and during lay down were found.

Intercept Solution:

The Sikorsky 73 A helicopters were wrapped with one layer of 8mil Intercept Shrink Film plus a second layer of 8mil Power Shrink for UV protection. A zipper window for easy access was installed, allowing inspection and change of desiccant. Intercept Foam was placed in the cabin for extra protection of sensitive electronic components.

Result:

- Prevention of Corrosion during sea shipment

- Protection against contamination

- During road transportation protection against wind, impact from stones and birds

Museum & Archival

Museums usually only display a fraction of their art works publicly. Most items are stored safely long-term. Despite using the most sophisticated methods pollution in the form of corrosive gases affects the often priceless items. Intercept as a volatile-free material can protect art works without harming them. Items include paintings, metal objects of all kinds, garments, fabrics, jewelry in general, coins, parchments, etc.

- Suitable for long-term storage in museum vaults

- Preventing of pollutants to affect art works

- 100% volatile free, art works are not influenced by the material

- No additives like oils or wax used that may harm art works

- Protection of silver items against tarnish

- Protection without scratching surface

Subject Case:

Protection of the “Samuel Adams and Paul Revere” Time Capsule

Situation:

The Samuel Adams and Paul Revere Time Capsule is a time capsule that was located in a cornerstone of the Massachusetts State House. It is believed to have been buried in 1795 by then-Governor Samuel Adams and Paul Revere. It is the oldest known time capsule in the United States. Pam Hatchfield, a leading conservator from the Boston Museum of Fine Arts was chosen to spearhead and lead the removal process and to determine how to handle, display, stabilize and re-pack these items for the return to the wall.

Prior to the Time Capsule was removed, Corrosion Intercept film was delivered to the Boston Museum of Fine Arts. The easily recognized copper film was used to cover all surfaces that the Time Capsule and all items from it were laid and displayed on. No other material was considered.

Intercept Solution:

The Corrosion Intercept film provided an underlayment for all items placed on display. The Corrosion Intercept product was then fabricated into various bags and holders to enclose each item in the Time Capsule, as well as the capsule itself, prior to re0inserting it into the wall.

Result:

- Protection for the items from all pollutant gases

- Isolation of these sensitive items from boxes and provision of a contaminating-free placement

- Film and bags that will continue to protect the sensitive items after they were put back

- Effective protection that provides stable protection without out-gassings or volatiles – safe

Situation:

Leading museums, including the Smithsonian, have noted that a substantial amount of degradation and damage to canvases, drawings and other hanging artwork comes through the walls, especially exterior walls. It is critical to protect the back of paintings to stop or slow the damage that these gases can have.

There are backing boards that use micro sieve technology – technology developed by the oil and gas industry to trap specific gases or liquids in glass spheres. The problem is that for micro sieves to be effective the levels of pollutants need to be in excess of 1 to 2 ppm (parts per million), below these high levels they lose their efficacy. These levels are not typically seen in museums, and once levels drop below these high points the efficacy still drops off, leaving dangerous levels of gases that can do significant damage to canvases, paper and other painting substrates.

Intercept Solution:

Instead of using a backing board, many museums have purchased Corrosion Intercept film and adhere with archival glue or staples to the frame. The Corrosion Intercept reacts with and permanently neutralizes the corrosive gases (pollutants) keeping them from the artwork.

Result:

- Protection for the artwork for even trace levels of pollutant gases (this is critical because damage can occur from H2S at levels as low as 35 ppb – parts per billion)

- Film that changes color to show that it is working and indicates when it needs to be changed

- Effective protection that provides stable protection with no out-gassings or volatiles – safe